What points should the food manufacturing industry consider when working on HACCP?

Business Q&A

December 22, 2021

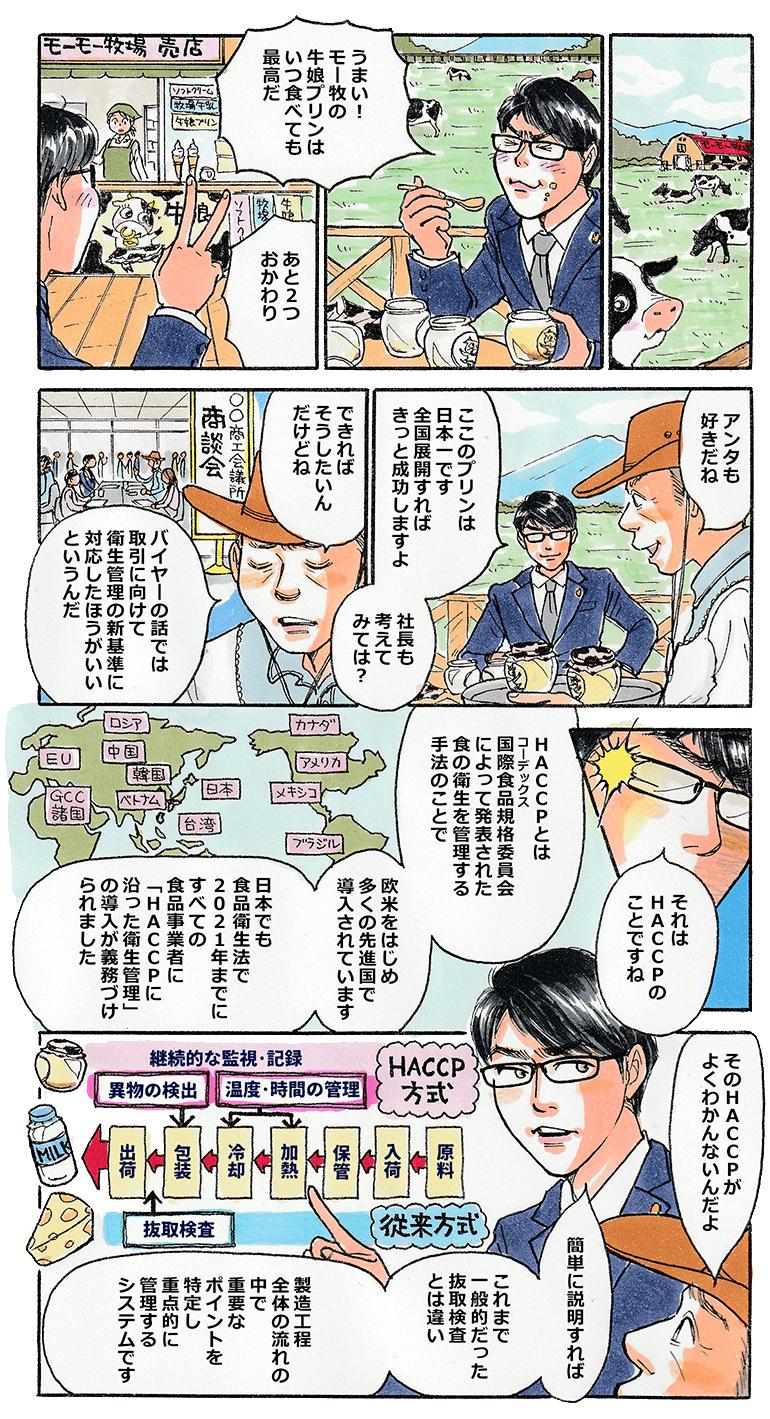

We run a 30-year-old food manufacturing company with seven employees. From June 1, 2021, what kind of points should I consider regarding the mandatory implementation of hygiene management in accordance with HACCP in principle?

Answer

On the website of the Ministry of Health, Labor and Welfare, a handbook for sanitation management that incorporates the concept of HACCP is published for each type of business. Please refer to this manual and follow the 7 principles and 12 procedures of HACCP. At the same time, the "food sanitation monitoring sheet" used by food sanitation inspectors at public health centers, etc. during monitoring and guidance has also been changed to a format that incorporates the HACCP concept. Become. After receiving supervision and guidance, some local governments issue a "Certificate of Sanitation Management Implementation in accordance with HACCP", so it can be used as an objective certificate if you do not receive third-party certification.

There are two ways to approach HACCP.

Hygiene management based on HACCP | Hygiene management incorporating the concept of HACCP | |

|---|---|---|

Target company | Large-scale business slaughterhouse poultry processing plant | Small businesses, etc.Examples) Manufacture and sale of sweets and tofu, sale of meat and seafood, manufacturing of side dishes and bread, greengrocers, rice stores, etc. |

Hygiene management method | Based on the 7 principles of HACCP, the food business operators themselves create and manage | Simplified management with reference to manuals created by industry groups |

When based on the 7 principles of HACCP

First, let's check the procedure. If you proceed along the following 12 steps, you can work while covering the 7 principles.

Let's discuss together. Let's prepare a system in which the person in charge of each department can participate so that all the information of the product can be consolidated.

Write down what the product you are making looks like.

Write down who the product is for and how it can be eaten.

Write how to make the product. Each person in charge writes out a series of flows for each item to be used, such as the main raw material, other raw materials, and packaging materials. It would be nice to be able to include things that need to be managed, such as temperature and time, at this time.

Check the manufacturing process and diagrams created in step 4 on site and correct them if they are incorrect. It's a hassle, but by doing this check, it's an important step to understand what's happening at the actual site.

Think about what kind of hazards are hidden in each manufacturing process. A hazard is something that causes an adverse effect on health. In addition to harmful microorganisms, we list all possible substances such as chemicals and hard foreign substances.

Find the processes that must be particularly tightly controlled to prevent health hazards. This is the CCP (critical control point). Find out where the processes are to request, remove or reduce hazards that may arise from raw materials or the manufacturing environment and cause health hazards.

Determine the criteria for managing the process determined in step 7. Standards are set by color, shape, numerical value, etc. Safety cannot be ensured if this standard is not met.

Make sure the standards you set in step 8 are consistently met. In addition to the temperature and time of ovens and sterilization tanks, the temperature of cooling equipment, the accuracy of metal detectors, etc., it is also possible to check visually.

If a problem occurs during the process, decide in advance how to improve it so that it can be corrected. Keeping improved records and reviewing them from time to time can help reduce complaints.

Regularly, we will review whether the plan so far is functioning effectively. It is important to check whether important and process records are being checked and whether corrective measures are being taken when problems occur.

Record the management status of each process. Not only is it proof that HACCP has been implemented, but reviewing the records will also help us to make future improvements and investigate the cause of problems when they occur.

For more information, the Ministry of Health, Labor and Welfare has set up a special page and has compiled information related to HACCP, so please refer to the following web page.

Source: Ministry of Health, Labor and Welfare