Why 2025 Is the Year of 3D Printing Breakthroughs?

3D printing will reach unprecedented heights in 2025, with advances altering how industries approach manufacturing and innovation. This breakthrough technology advances in speed, materials, and intelligence, allowing for faster, more precise, and efficient manufacturing. These innovations not only improve existing processes but also broaden 3D printing's applications in healthcare, construction, and other industries. Innovations such as the AnkerMake M5 are making excellent, high-speed printing more accessible, demonstrating why 2025 will be a watershed moment in the industry. These advancements promise to expand the possibilities of 3D printing for both pros and beginners.

What Innovations Are Driving 3D Printing in 2025?

Advances in Materials Science

In 2025, new materials will revolutionize 3D printing by improving its strength, durability, and sustainability. Composites, bioplastics, and metal alloys have advanced to allow for more varied uses across industries. Biocompatible materials, for example, are helping to advance healthcare, while lightweight alloys are improving aerospace and automotive manufacturing. Products such as the "AnkerMake M5 + 4 kg Filament" demonstrate these improvements by supporting materials such as PLA, TPU, and ABS for a variety of applications. Such developments render 3D printing more versatile and capable of addressing changing industrial demands, paving the way for breakthroughs in customization and performance.

Breakthroughs in 3D Printing Speed and Precision

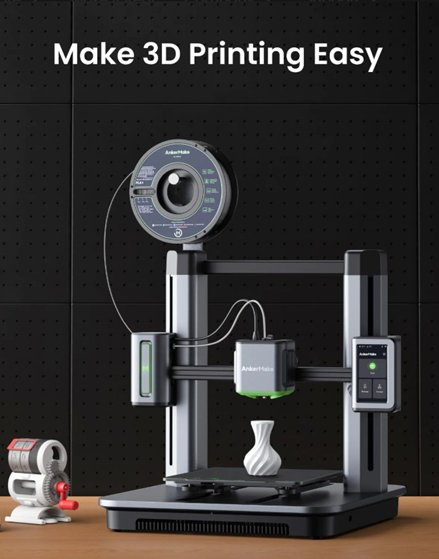

Significant advances in speed and precision will define 3D printing by 2025. The AnkerMake M5 printer features PowerBoost™ 2.0 technology, which reduces printing time by 80% while maintaining 0.1 mm precision. The ultra-direct extruder and die-cast aluminum alloy construction provide consistent quality, even at a staggering 500 mm/s speed. These innovations enable high-volume production and specific customization, achieving a balance of efficiency and performance. Industries may now increase operations while getting superior outcomes, establishing a new benchmark for 3D printing capabilities.

Integration of AI and Machine Learning in 3D Printing

Artificial intelligence (AI) is changing 3D printing by optimizing operations and improving quality. AI-powered technologies, such as the built-in AI camera in the AnkerMake M5, enable real-time monitoring and error detection. Automatic time-lapse production and machine-learning optimizations boost efficiency and reduce waste. These advancements make 3D printing more accessible, enabling both experts and beginners to produce professional results. As AI becomes more integrated, consumers benefit from smarter, faster, and more intuitive 3D printing experiences, making sophisticated manufacturing more accessible than ever.

Which Industries Will Benefit Most from 3D Printing in 2025?

Healthcare and Bioprinting

Customized surgical tools, implants, and prostheses are all within reach thanks to 3D printing, which is revolutionizing the medical field. Bioprinting technology has revolutionized the manufacturing of tissues and organs, meeting crucial medicinal needs. Printers like the AnkerMake M5 are able to produce the fine details needed for these kinds of uses by printing on biocompatible materials. Improving patient outcomes, reducing expenses, and addressing global healthcare challenges are all goals that these developments aim to achieve. 3D printing is continuing to transform medical innovation with its mix of speed and accuracy, making life-saving treatments more accessible.

Aerospace and Automotive Manufacturing

3D printing allows the aerospace and automotive industries to produce complex parts that are lightweight and enhance performance. Lightweight materials improve fuel economy and environmental friendliness; examples are titanium alloys and carbon composites. With the AnkerMake M5's rapid mode, you can streamline your production and development processes, which means you can innovate faster. Complex components that were previously impossible to fabricate using conventional methods are now within reach, thanks to design diversity and precision. Because of these benefits, 3D printing is becoming an essential tool in contemporary design and industry.

Construction and Housing Solutions

Construction companies are adopting 3D printing to develop inexpensive and sustainable housing options. Large-scale printers produce modular components rapidly and efficiently, lowering costs and waste. The auto-leveling system in the AnkerMake M5 ensures consistency and quality in these applications. By allowing for the quick creation of house elements, 3D printing addresses global issues such as housing shortages and sustainability. This technology's precision and scalability make it a great option for modern construction needs, changing building design and construction.

Conclusion

The year 2025 is a watershed moment for 3D printing, with advances in materials, speed, and AI integration pushing its widespread acceptance across industries. These innovations serve a variety of industries, including healthcare, aircraft, and construction. Products like the "AnkerMake M5 + 4 kg Filament" demonstrate how 3D printing technology is growing quicker, smarter, and more affordable. Now is the ideal moment to investigate 3D printing's potential as these innovations keep expanding the realm of what is possible, whether you're a professional or just starting with the best 3d printer for beginners.