Advancements in 3D Printing Technology

3D printing technology has altered sectors by allowing for rapid prototyping, efficient manufacturing, and personalized medicinal uses. Continuous improvements in 2025 have increased speed, precision, and material capacities, making this technology more impactful across a variety of industries. AnkerMake tops the market with its innovative M5 and M5C 3D printers, which offer cutting-edge capabilities for both professionals and enthusiasts. These printers are intended to address the growing demand for versatile, user-friendly solutions that push the limits of 3D printing's capabilities. This blog delves into the newest advancements, business applications, and future trends affecting the 3D printing world.

What Are the Latest Breakthroughs in 3D Printing?

Development of High-Performance 3D Printing Materials

The introduction of improved 3D printing materials has expanded the range of applications across sectors. High-temperature polymers, carbon fiber composites, and metal materials enable the creation of more durable and complicated goods. AnkerMake's M5 3D Printer supports these materials, thanks to its all-metal hotends that can print at temperatures of up to 300°C. These upgrades give users the ability to generate high-precision models for industrial applications and artistic ideas. Such developments increase the versatility of 3D printing, allowing industries to attain high performance, durability, and adaptability in their projects and products.

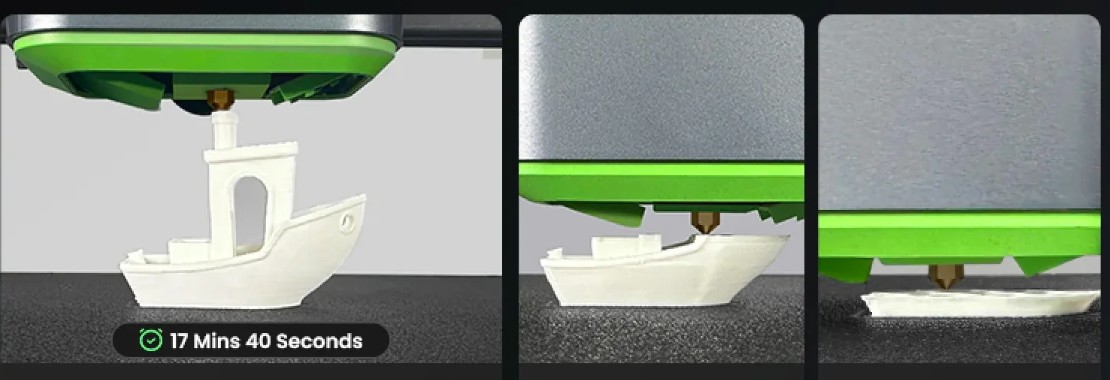

Innovations in Speed and Accuracy of 3D Printers

Speed and accuracy remain significant drivers of growth in 3D printing technology. Innovations like AnkerMake's M5, equipped with PowerBoost™ 3.0, enable printing at an unparalleled speed of 500 mm/s while keeping precision at 0.1 mm. This technology cuts production time by 80%, making it suited for both small-scale projects and large-scale industrial applications. By incorporating ultra-direct extrusion technology and powerful motion control algorithms, these printers give outstanding performance without compromising quality. Such developments give organizations speedier, more dependable solutions, guaranteeing they can fulfill rigorous production timetables with great precision.

Emerging Multi-Material Printing Capabilities

Multi-material 3D printing capabilities are transforming the design and manufacturing processes. Modern printers may incorporate stiff and flexible materials in a single build, eliminating the need for complicated assembly procedures. This allows for the construction of complicated objects with a variety of attributes, which improves product functionality and efficiency. AnkerMake's M5 printer, with its high speed and multi-material compatibility, helps diverse industries explore new possibilities. These advancements promote creativity and efficiency, allowing organizations to manufacture complicated goods that satisfy individual needs without losing quality or time.

How Are Businesses Using 3D Printing in 2025?

Transformations in Manufacturing and Prototyping

Organizations can now develop faster and cheaper thanks to 3D printing, which has revolutionized production and prototyping. The M5 3D Printer from AnkerMake allows businesses to produce high-quality prototypes and final products at record-breaking speeds. This technology streamlines the design process, allows for on-demand production, and decreases waste. Organizations may optimize processes, reduce time-to-market, and stay competitive by making use of these improved capabilities. Businesses are rethinking their approaches to product development and production as 3D printing becomes more integrated into conventional manufacturing processes. This brings up exciting new opportunities for customization and innovation.

Advancements in Healthcare and Bioprinting

Healthcare has embraced 3D printing to develop personalized solutions such as prosthetics, implants, and surgical instruments. Bioprinting, which uses living cells to create tissue structures, is a growing field with transformative potential. The AnkerMake M5C printer provides precision and material compatibility, allowing healthcare practitioners to manufacture intricate and customized equipment. These breakthroughs improve patient outcomes by enabling personalized medical solutions. As the technology becomes more widely available, the healthcare industry will continue to use 3D printing for novel applications that improve efficiency and stimulate advances in medical research and treatment.

Impact on Aerospace and Automotive Industries

The use of 3D printing has revolutionized several industries, including aerospace and automotive, by creating lightweight and long-lasting components that enhance performance at a reduced cost. These sectors have high-speed, precise manufacturing needs, and AnkerMake's M5 printer meets those demands. Companies can make innovative components with better fuel efficiency and performance because of their capacity to produce complex shapes. Lead times and material waste are both reduced thanks to 3D printing's ability to optimize manufacturing processes. Because of these features, it is a must-have for businesses that want to stay in business and stay ahead of the competition in a dynamic market.

What's Next for 3D Printing Technology?

Sustainable 3D Printing Practices

Sustainability is becoming a primary concern in 3D printing as innovations such as recycled filaments and energy-efficient designs gain acceptance. AnkerMake's M5 printer cuts energy consumption by 59% while reducing printing time by 70%, making it an environmentally responsible choice. These improvements allow firms to reduce their environmental footprint while maintaining production. As enterprises adopt more sustainable practices, 3D printing will play an important role in decreasing waste and supporting greener production methods. Such advancements ensure that technology remains in line with global sustainability goals, promoting a more ecologically responsible future.

Artificial Intelligence in 3D Printing Workflow

Artificial intelligence (AI) is improving 3D printing workflows by automating error detection, optimizing designs, and increasing productivity. AnkerMake's M5 printer incorporates AI-powered features, including real-time monitoring via its intelligent camera and adaptive algorithms, resulting in faultless prints. These features enable people to concentrate on creativity while the system tackles complicated chores. By integrating AI, 3D printing technology becomes more accessible and dependable, allowing experts and enthusiasts to get better results with less work. This connection is defining the future of 3D printing, making it more intelligent and efficient.

Predictions for Future Consumer Applications

Consumers will be able to make unique things such as home décor, tools, and personal gadgets as 3D printing becomes more accessible. AnkerMake's M5C printer has user-friendly features and fast printing speeds, allowing users to easily bring their ideas to life. As technology grows more accessible and adaptable, its use in everyday life will grow. From amateurs to small enterprises, 3D printing will enable individuals to invent and personalize things, paving the way for an unlimited future of creation. This progression demonstrates 3D printing's transformational potential.

Conclusion

Advancements in 3D printing technology are altering industries by increasing speed, precision, and versatility. Businesses in manufacturing, healthcare, aerospace, and other industries are embracing this innovation to increase efficiency and customization. AnkerMake's M5 and M5C printers let professionals and hobbyists explore the endless possibilities of 3D printing. With sustainability and artificial intelligence driving the future, this technology will continue to be a cornerstone of innovation. Are you ready to revolutionize your projects? Discover AnkerMake's revolutionary 3d printers and take the next step in your 3D printing journey today.